Soil Thermal Resistivity: Why Your Cable Sizing Could Be 25% Off

Soil thermal resistivity can swing your cable sizing by 25% or more. See real heat maps showing why that default 1.2 K·m/W value is probably wrong. Real IEC 60287 data for 630mm² aluminum cables.

You know that default soil resistivity value everyone uses? 1.2 K·m/W?

Yeah, it's probably wrong.

I ran the numbers on a 630mm² aluminum cable. The difference between wet and dry soil? Your cable sizing could be 25% off.

That's the difference between a working cable and a stressed, overheated cable.

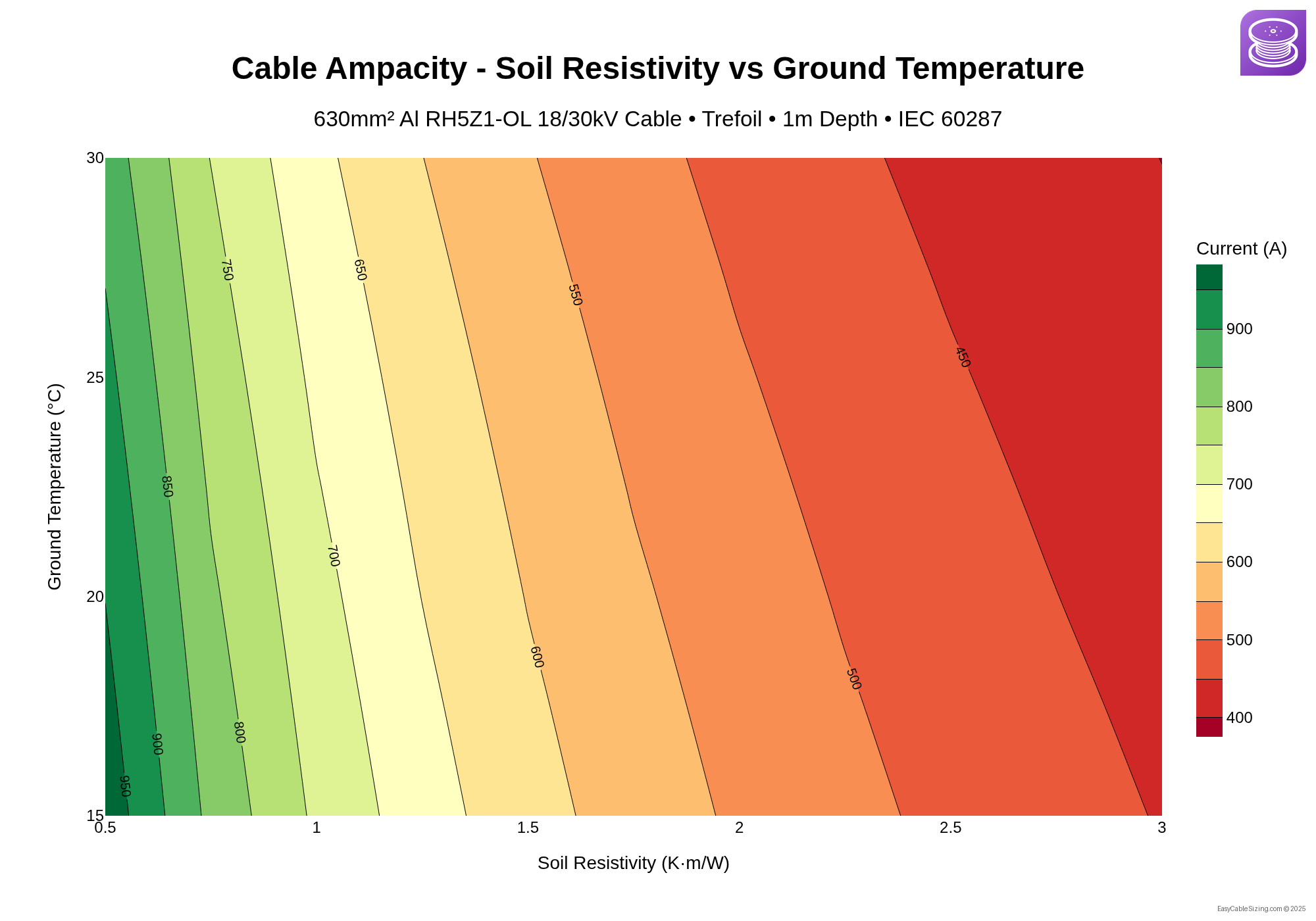

What the Heat Map Actually Shows

Look at this 30kV cable data - each point is a full IEC 60287-2-1 calculation:

15°C ground temp:

- Dry sand (2.5 K·m/W): 488.2A

- Wet soil (0.7 K·m/W): 860.7A

That's not a typo. Same cable. 76% more capacity in wet conditions.

The calculation accounts for conductor losses (I²R), dielectric losses (minimal at 30kV), sheath losses, thermal resistance through each layer, and the two big variables - soil thermal resistance and ground temperature.

But here's the thing - you never confidently know the soil resistivity.

15→25°C ground temp:

Everything drops ~7%.

How This Goes Wrong

Scenario 1: You Undersize

Designed for 1.2 K·m/W and got well drained, dry sand.

- Expected: ~684A, so used 630mm Al cable

- Reality: ~488A capacity, and cable running HOT!

- Result: Replace the whole run - you could be looking at about €160,000 per km with trenching and upsized cable!

Scenario 2: You Oversize

Designed for 1.2 K·m/W and got constantly soggy clay at 0.7 K·m/W

- Expected: ~684A, again used the 630mm Al

- Reality: ~860A capacity, and cable under utilised and at a premium! 400mm Al would have worked.

- Wasted: €15,000 per km

Both scenarios happen. I've seen both.

How Soil Resistivity Actually Works

Heat from your cable has to go somewhere. In buried cables, it dissipates into the surrounding soil.

Soil thermal resistivity measures how well (or poorly) soil conducts that heat away. Lower values mean heat escapes faster - your cable runs cooler and can carry more current. Higher values trap heat - your cable runs hotter and you're forced to derate.

Think of it like insulation in reverse. High thermal resistivity = good insulation for your house, terrible for your cable.

Measuring It: Thermal Needle Probes

The standard method uses a thermal needle probe - basically a heated needle pushed into the soil at cable depth.

Here's how it works:

- Probe heats to a known temperature

- Measures how fast heat dissipates into surrounding soil

- Calculates thermal resistivity from the rate of heat loss

Takes about 10-15 minutes per test point. You'd typically test at multiple locations along the cable route and at the actual burial depth.

The probe follows IEEE 442 or IEC 60287-3-1 methodology. Results are in K·m/W - the higher the number, the worse your cable capacity.

How to Account for Soil Resistivity in Cable Design

1. Test the Soil

Thermal probe testing? €3,000-5,000 depending on depth and test points.

Potential savings: €160,000 if you avoid replacement.

ROI: 30-50x

Still a no-brainer.

2. Know Your Seasons

Winter (wet): 0.7-1.0 K·m/W

Summer (dry): 1.5-2.5 K·m/W

Pick your design point.

3. Depth Changes Everything

Surface (0-0.5m): Wild swings

1m depth: Reasonably stable

2m+: Most consistent

Our data shows 1m depth.

Soil Types That Matter

| Soil Type | Moisture | Resistivity (K·m/W)* | Cable Capacity |

|---|---|---|---|

| Clay | Wet | 0.7-0.9 | 100% |

| Clay | Dry | 1.2-1.5 | 85% |

| Sand | Wet | 1.0-1.2 | 90% |

| Sand | Dry | 2.0-3.0 | 60% |

| Backfill | Controlled | 0.7-1.0 | 95-100% |

*IEC 60287-3-1 and IEEE 442 values. Your site will vary.

Dry sand kills your ratings. Every time.

IEC 60287-3-1 lists country defaults: Spain uses 1.0 K·m/W, UK uses 1.2. Both could be miles off for your actual site.

When It Goes Wrong, Everyone Asks "What Soil Value Did You Use?"

So:

- Stop using default values

- Test the soil (€5k beats €200k)

- Use seasonal ratings

- Document your assumptions

Let's Talk Money on a 5km 30kV Run

- Conservative design: €600k (25% oversized)

- With soil testing: €525k

- Savings: €75k

- Testing cost: €5k

That's 15:1 ROI.

Why aren't you testing soil again?

Try It Yourself

Start calculating with real soil data at EasyCableSizing.com

7-day free trial. Full IEC 60287 calculations.

Technical bit: 630mm² Al XLPE (18/30kV, RH5Z1-AL type), trefoil, 1m depth, IEC 60287, steady-state.